As the demand for efficient and streamlined warehouse operations continues to grow, businesses are turning to innovative solutions such as intralogistics robots. These advanced robotic systems have revolutionized the way goods are handled, sorted, and transported within a warehouse environment.

The Advantages of Intralogistics Robots

Intralogistics robots offer numerous advantages that significantly improve warehouse efficiency. Firstly, these robots can autonomously navigate through complex environments using advanced sensors and mapping technologies. This eliminates the need for human intervention in routine tasks such as picking and transporting items, allowing employees to focus on more value-added activities.

Secondly, intralogistics robots are capable of working around the clock without fatigue or breaks. They can tirelessly perform repetitive tasks with precision and consistency, leading to increased productivity levels within the warehouse.

Furthermore, these robots can optimize storage space by efficiently organizing inventory based on real-time data analysis. By utilizing their intelligent algorithms, they can identify optimal storage locations for different products, reducing unnecessary movements and maximizing overall capacity utilization.

In addition to improving operational efficiency, intralogistics robots also enhance workplace safety. With their built-in collision avoidance systems and ability to interact safely with humans in shared spaces, they minimize the risk of accidents or injuries commonly associated with traditional material handling equipment.

Youibot: A Leading Provider of Intralogistics Robots

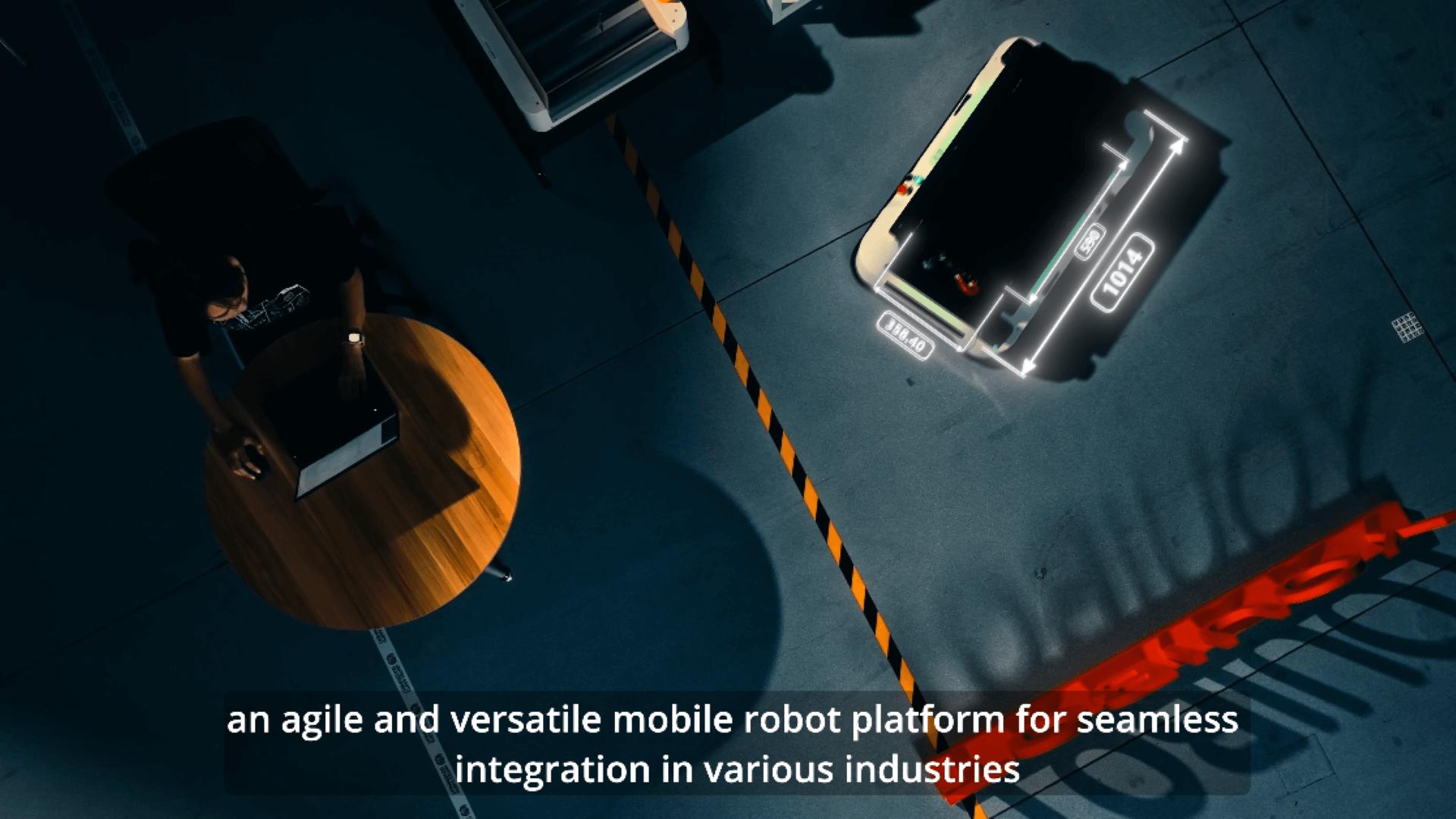

One prominent player in this field is Youibot – a leading provider of intralogistics robot solutions. Their state-of-the-art robotic systems combine cutting-edge technology with user-friendly interfaces designed specifically for industrial applications.

Youibot’s range of intralogistics robots includes autonomous mobile platforms equipped with various modules tailored for specific tasks such as pallet handling or order picking. These robots can seamlessly integrate with existing warehouse management systems, enabling seamless communication and coordination between different components of the supply chain.

With a strong focus on research and development, Youibot continuously strives to enhance their robots’ capabilities. They are committed to delivering innovative solutions that address the evolving needs of modern warehouses, ensuring optimal performance and customer satisfaction.

The Applications of Mobile Robots in Intralogistics

mobile robot applications within intralogistics encompass a wide range of tasks. These robots can efficiently transport goods from one location to another, eliminating manual labor and reducing operational costs. They can also be utilized for inventory management by autonomously scanning barcodes or RFID tags, providing real-time data updates for accurate stock control.

In addition, mobile robots can collaborate with human workers in order picking processes. By working alongside employees, they optimize efficiency by suggesting optimized routes or dynamically adjusting task assignments based on workload distribution.

Furthermore, these versatile robots can adapt to changing demands within the warehouse environment. With modular designs that allow easy customization and integration of additional functionalities such as robotic arms or conveyor belts, they offer flexibility in meeting specific operational requirements.

In Conclusion

Intralogistics robots have revolutionized warehouse operations by offering numerous advantages such as increased efficiency, improved safety measures, and optimized space utilization. Companies like Youibot are at the forefront of this technological advancement with their advanced intralogistics robot solutions designed specifically for industrial applications. As mobile robot applications continue to evolve and expand within the intralogistics sector, businesses stand to benefit from enhanced productivity levels and streamlined operations.