In today’s rapidly evolving technological landscape, smart manufacturing 4.0 has emerged as a game-changer in the industrial sector. This revolutionary concept combines cutting-edge technologies such as artificial intelligence, big data analytics, and Internet of Things (IoT) to optimize production processes and enhance efficiency.

The Power of Smart Manufacturing 4.0

Smart manufacturing 4.0 brings forth a plethora of benefits for businesses across various industries. By seamlessly integrating machines, systems, and humans through advanced connectivity, it enables real-time monitoring and analysis of production data.

This technology-driven approach empowers manufacturers to make informed decisions promptly based on accurate insights derived from extensive data sets. It not only enhances productivity but also minimizes downtime by predicting maintenance requirements before any major breakdown occurs.

JVTECH: Pioneering Smart Manufacturing Solutions

One company at the forefront of smart manufacturing innovation is JVTECH – a leading provider of intelligent factory solutions. Leveraging their expertise in automation and digitalization technologies, they have successfully implemented smart manufacturing 4.0 principles in numerous factories worldwide.

By adopting JVTECH’s comprehensive suite of solutions encompassing robotics integration, predictive analytics, and cloud-based platforms, manufacturers can achieve seamless connectivity between different stages of production while optimizing resource allocation.

The Rise of Liquid Silicone Injection Molding Manufacturer

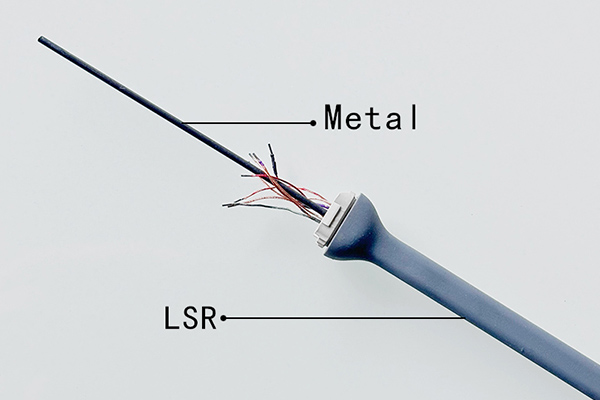

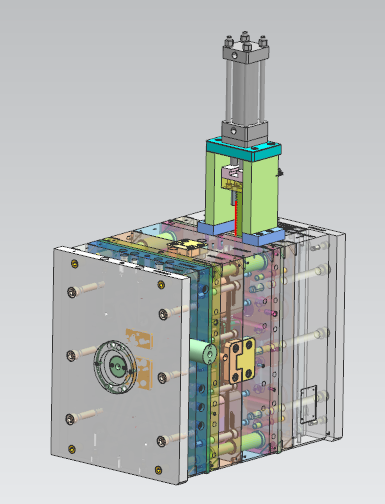

A key aspect within the realm of smart manufacturing is liquid silicone injection molding manufacturer – an innovative technique that revolutionizes traditional molding processes with its precision and versatility.

This method allows for the creation of complex shapes with high accuracy using liquid silicone rubber materials. With its ability to produce intricate designs efficiently while maintaining consistent quality standards throughout mass production runs, liquid silicone injection molding has gained significant traction in various industries such as medical devices and automotive components.

Conclusion: Embracing the Future of Manufacturing

In conclusion, smart manufacturing 4.0 is reshaping the landscape of production by leveraging advanced technologies to optimize efficiency and productivity. Companies like JVTECH are leading the way in providing intelligent factory solutions that enable seamless connectivity and data-driven decision-making.

Furthermore, emerging techniques like liquid silicone injection molding manufacturer offer manufacturers unprecedented capabilities to produce intricate designs with precision and consistency.

As we embrace this new era of manufacturing, it is crucial for businesses to adapt and invest in smart manufacturing 4.0 technologies to stay competitive in an increasingly digitalized world.